Tank and Pipeline Coatings Services Melbourne

In industries like oil and gas, water treatment, and chemicals, tanks and pipelines are essential infrastructure that need to be properly protected from various environmental and operational hazards. Tank and pipeline coatings are designed to safeguard these assets from corrosion, extreme temperatures, chemicals, and physical damage. At Profresh Painting Group, we offer specialized coating services for tanks and pipelines that ensure the long-term integrity and performance of your infrastructure.

What Are Tank and Pipeline Coatings?

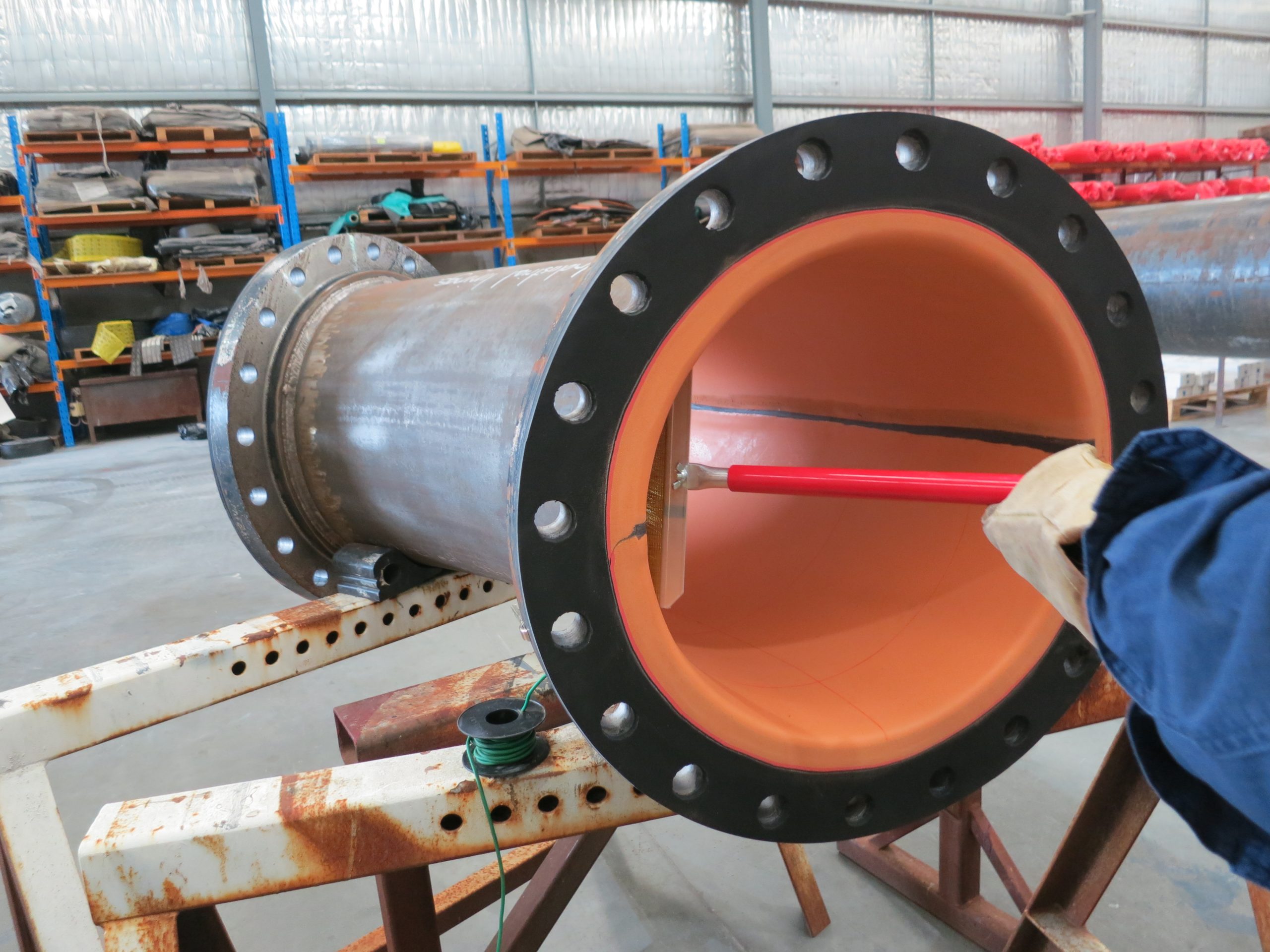

Tank and pipeline coatings are protective layers applied to storage tanks, pipes, and other critical infrastructure to prevent corrosion and wear. These coatings are typically made from materials like epoxy, polyurethane, or other advanced polymers, each designed to withstand specific conditions and environments. The primary purpose of these coatings is to extend the lifespan of your tanks and pipelines while reducing maintenance costs and the risk of system failure.

In addition to protecting against corrosion, tank and pipeline coatings also provide resistance to chemicals, extreme weather, and physical impacts, making them an essential investment in industries with harsh operating conditions. Protecting pipelines from corrosion and chemicals is essential in the oil and gas industry. Coatings ensure the long-term operation of pipelines while reducing the risk of leaks and failures. Coatings are used on tanks and pipes in water treatment facilities to prevent contamination and maintain water quality.

Benefits of Tank and Pipeline Coatings

Applying protective coatings to tanks and pipelines offers a range of significant benefits that protect both the assets and your business operations:

- Corrosion Prevention: Corrosion is one of the leading causes of damage to tanks and pipelines, especially in environments exposed to chemicals, moisture, and extreme temperatures. Protective coatings form an impermeable barrier that prevents corrosive substances from reaching the surface of the tank or pipeline, greatly extending their lifespan.

- Cost Savings on Maintenance: By reducing the need for frequent repairs and replacements, tank and pipeline coatings help businesses save on maintenance costs. Coated tanks and pipelines require less upkeep, meaning fewer downtime and greater operational efficiency.

- Chemical and Temperature Resistance: Tanks and pipelines are often exposed to harsh chemicals and extreme temperatures. Protective coatings are designed to withstand these conditions, preventing degradation and ensuring that your assets function effectively even in challenging environments.

- Improved Durability: Tank and pipeline coatings enhance the physical strength of the infrastructure. This additional layer of protection guards against mechanical damage, such as scratches and dents, ensuring the long-term integrity of your systems.

- Environmental Protection: Protecting tanks and pipelines from corrosion and leaks can help prevent environmental hazards. Coatings are designed to prevent the release of toxic materials into the environment, ensuring compliance with environmental regulations and reducing the risk of pollution.

Why Choose Profresh Painting Group for Tank and Pipeline Coatings?

At Profresh Painting Group, we understand the critical nature of tank and pipeline coatings for industries that rely on infrastructure to operate safely and efficiently. Our team of experts is highly trained in applying industrial-grade coatings that offer unmatched durability and protection. We use the highest quality materials to ensure that your tanks and pipelines are shielded from corrosion, physical damage, and harsh environmental conditions.

Our customized coating solutions are tailored to meet the unique needs of your industry, whether you're in oil and gas, water treatment, or another sector. Our commitment to quality and customer satisfaction sets us apart as a leading provider of tank and pipeline coating services in Melbourne. We ensure that each project is completed on time and with minimal disruption to your operations, so you can focus on running your business with confidence. If you need reliable, long-lasting tank and pipeline coatings, Profresh Painting Group is here to help. Contact us today to learn more about our services and how we can help protect your infrastructure for years to come.